|

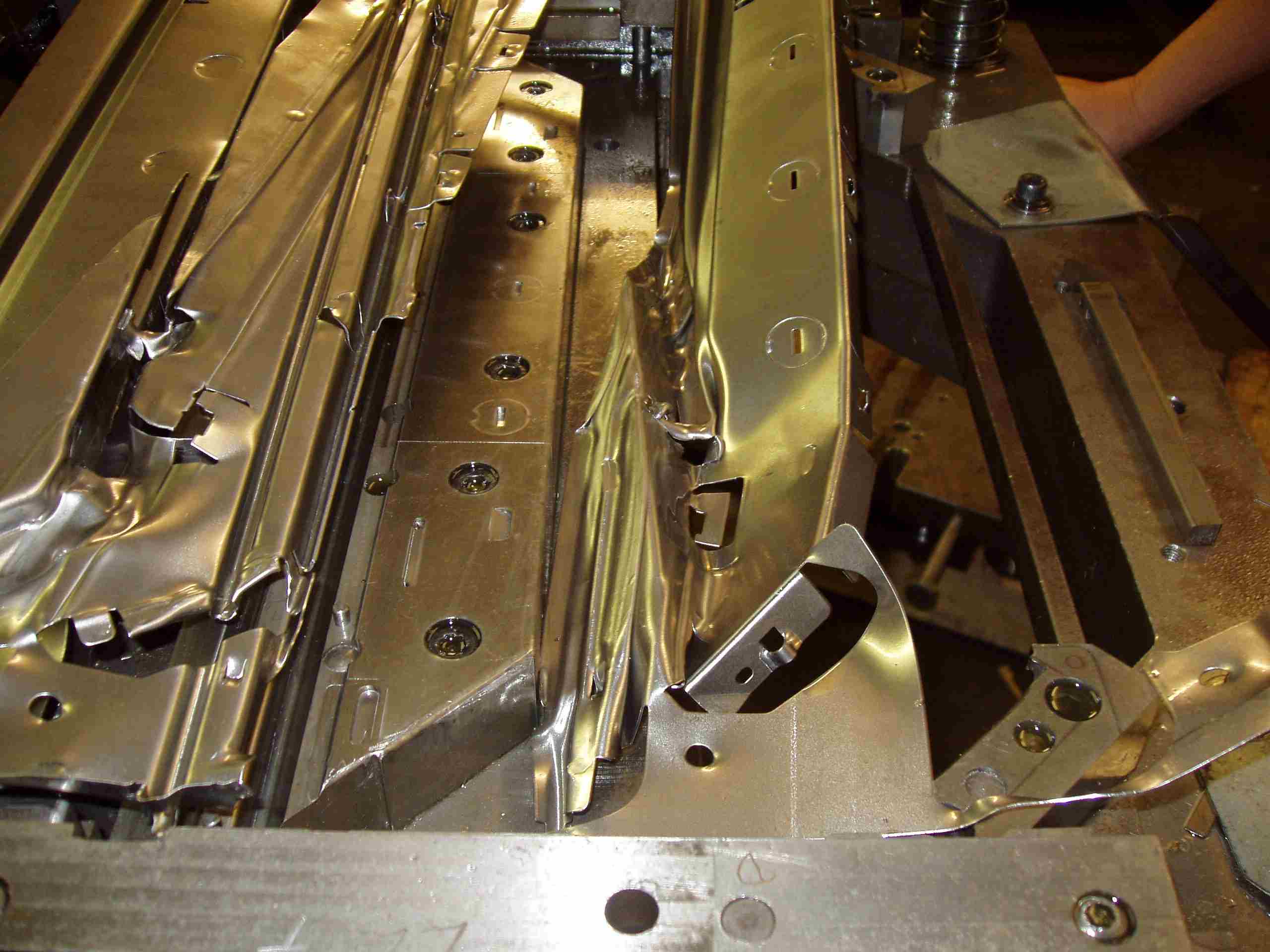

A tool for a particular part would periodically fail to eject the formed part and would feed more sheet steel in the tool. This would result in the next press cycle pressing the new sheet on the un-ejected part, causing breakage of the tool (seen right).

|

|

|

This would then necessitate the removal and repair of the tool at another companies premises which was costly and also resulted in orders using this pressing being delayed in delivery to the customer.

|

|

|

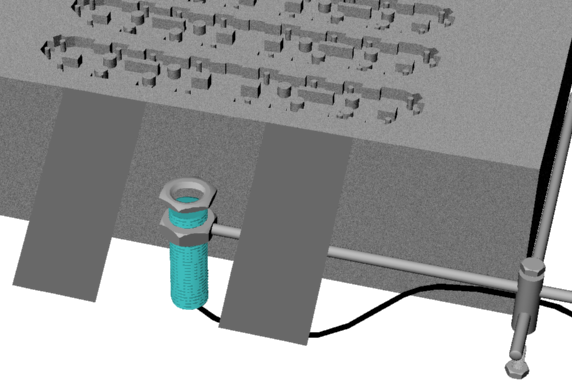

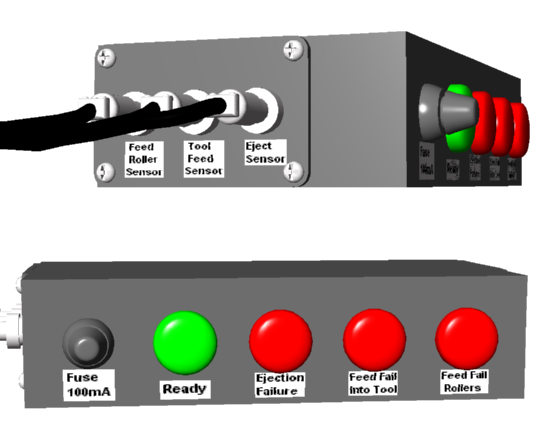

Sensors were added to the tool and press, and a detection system designed which was then integrated in to the press control system, thereby automatically preventing the press tool from closing if the part had not been properly ejected.

|

|

|

The cost of the system was recovered within a few interventions.

|

|