|

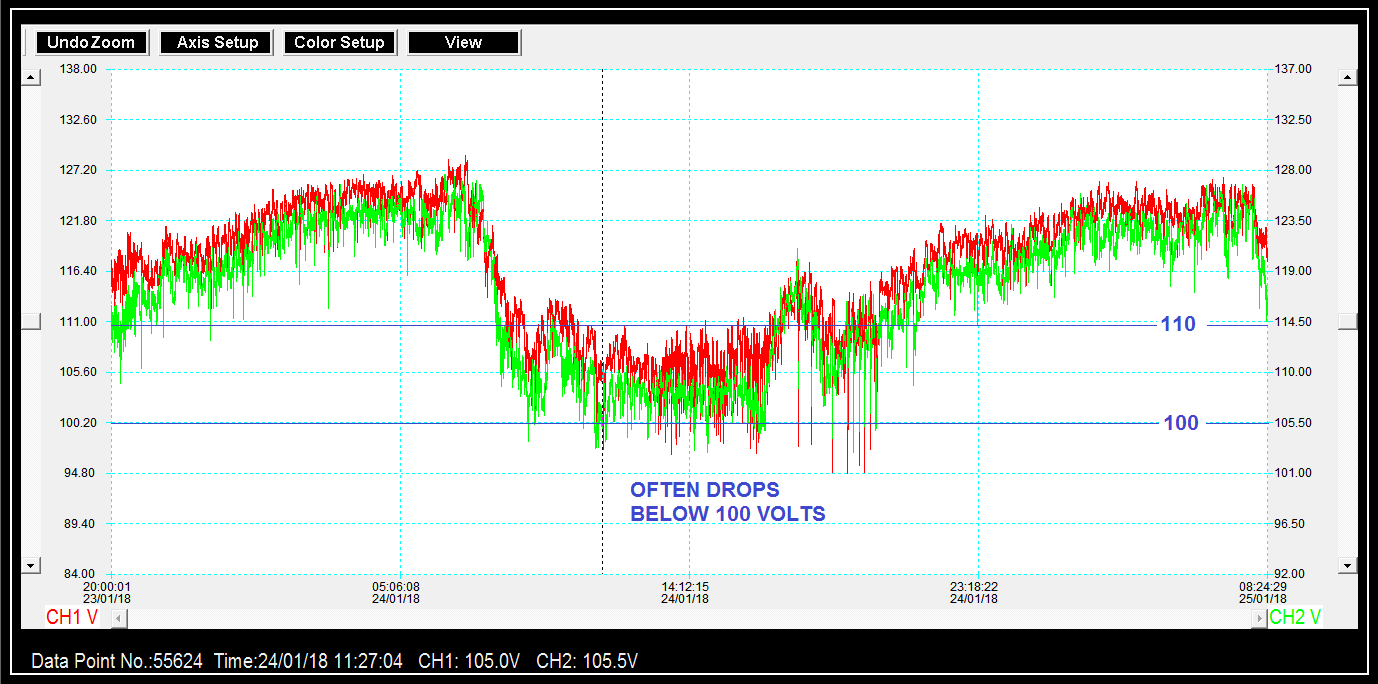

A refrigeration compressor system would go into automatic shutdown and recovery periodically. A data logger was attached to the power input to continually monitor the current and voltage through a 36 hour period.

|

|

|

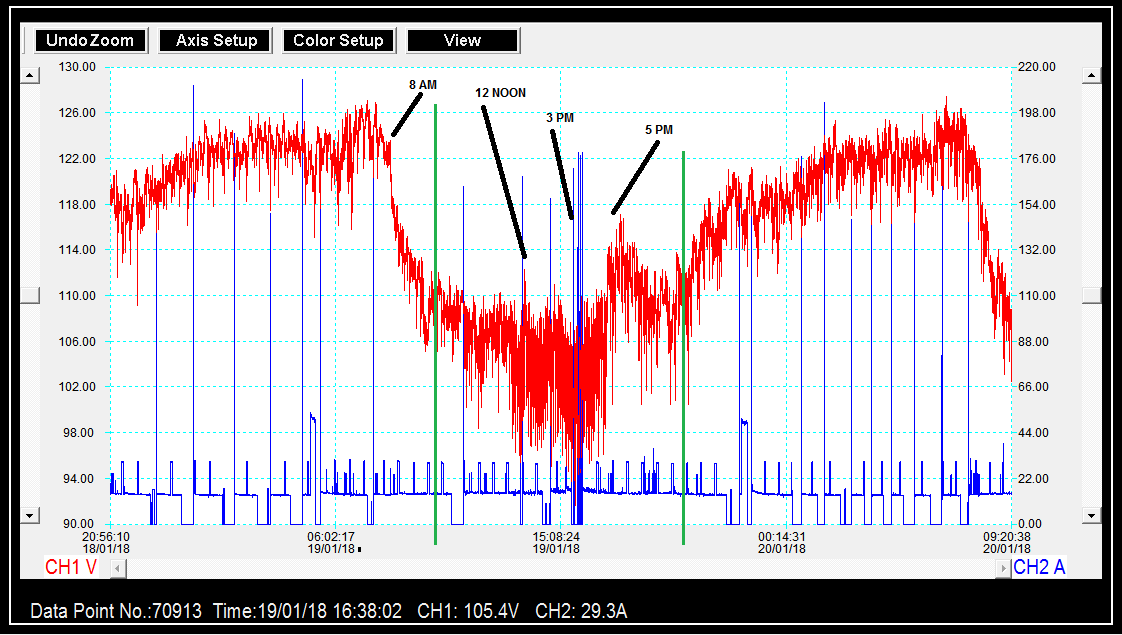

A graph of current and voltage from the logged data plotted indicates a voltage slump during normal work hours

|

|

|

The most severe problems were noted in the mid-afternoon period, which corresponded to the observed shutdown problems.

|

|

|

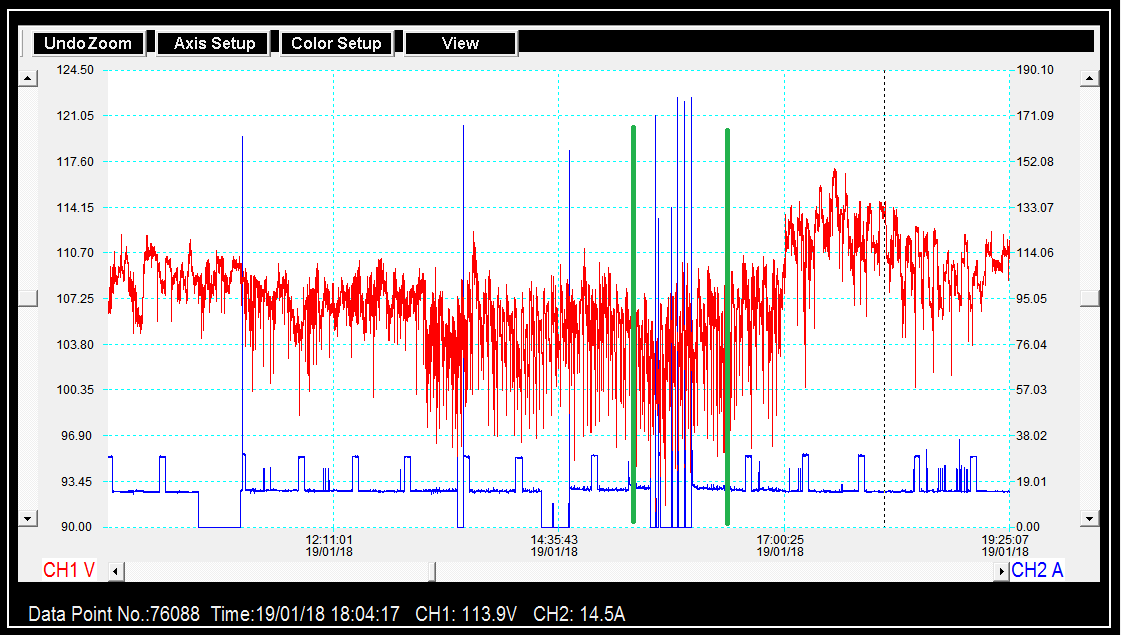

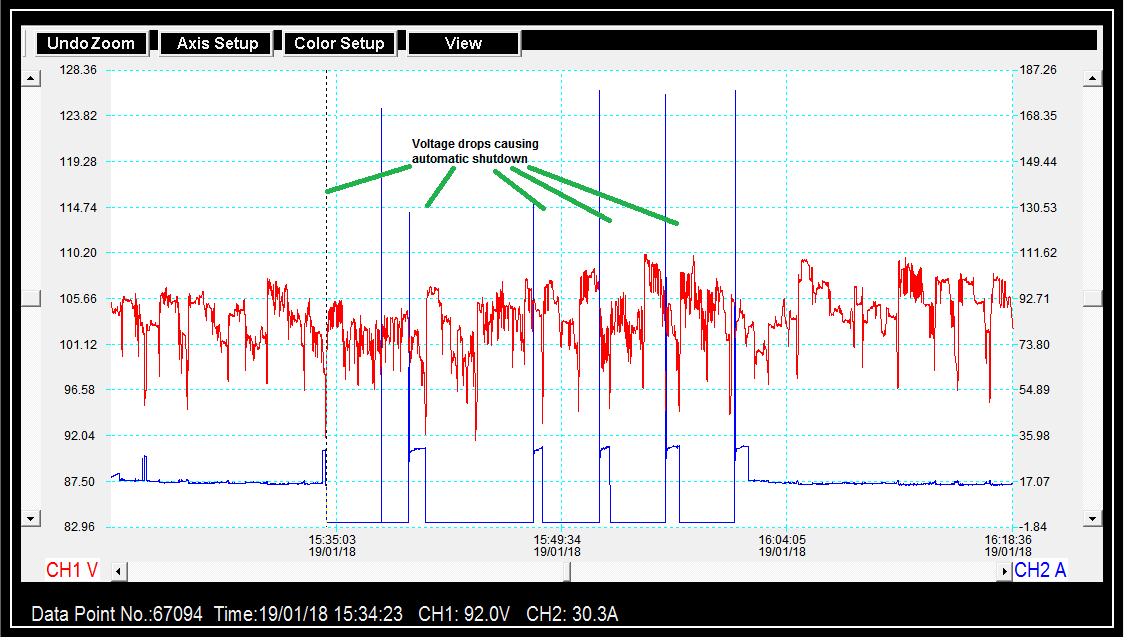

Zooming in to the 3 to 4 o clock times gives a clear cause and effect of the voltage dropping and the cut-off of the cooling system.

|

|

|

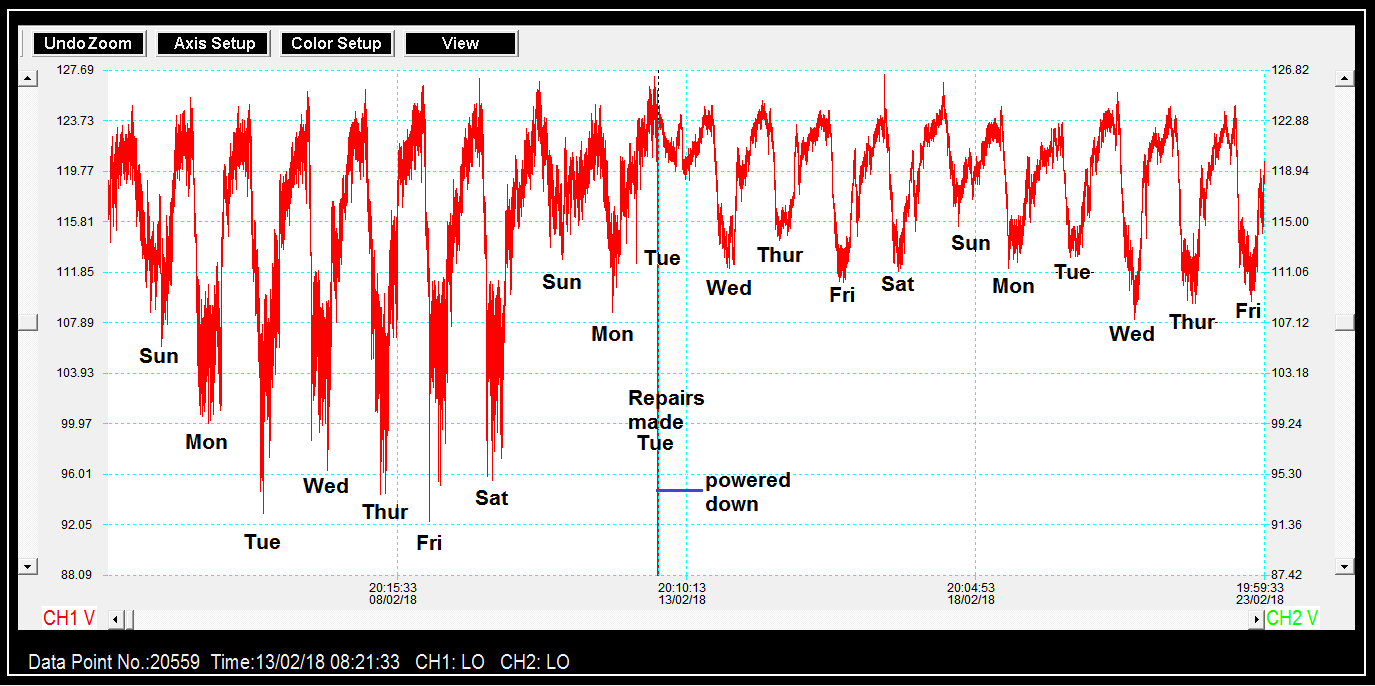

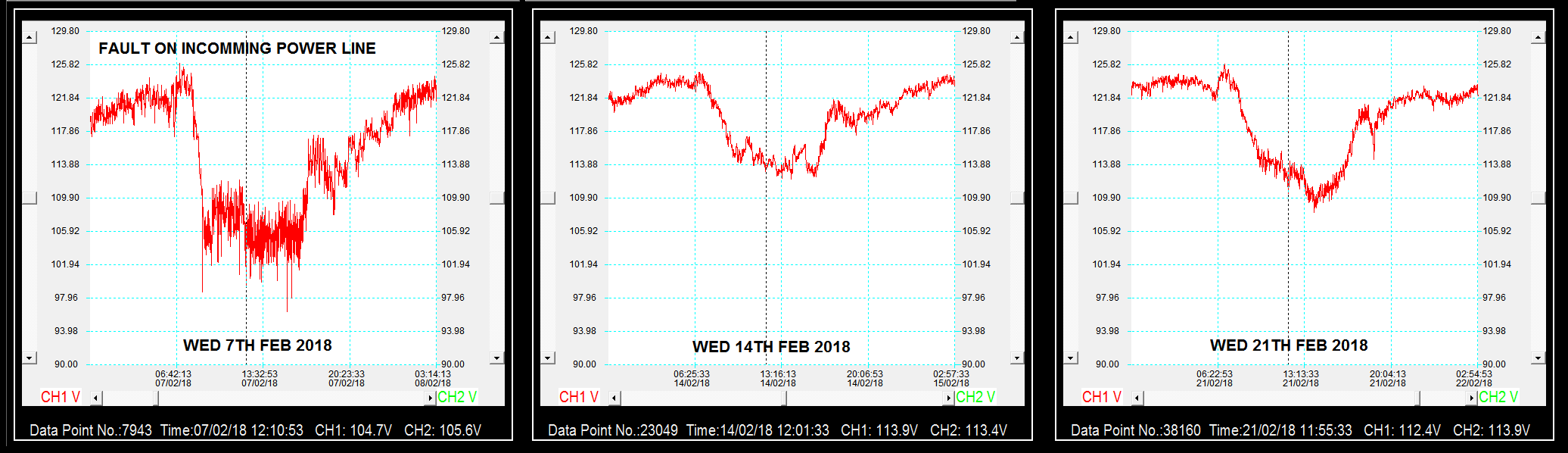

The power lines were logged again over a working day and the two phases were monitored and logged for voltage difference between phases.

|

|

|

the logger was put onto the power lines while further tests were carried out, having determined that the problems were external to the compound, T&TEC were contacted and

corrected the fault - root cause is not known.

|

|

|

Incoming voltages are now much improved and do not dip severely. No voltage below 100 volts detected after fault correction.

|

|